Industry knowledge

What is a milling cutter, and what are its applications?What are the different types of milling cutters?

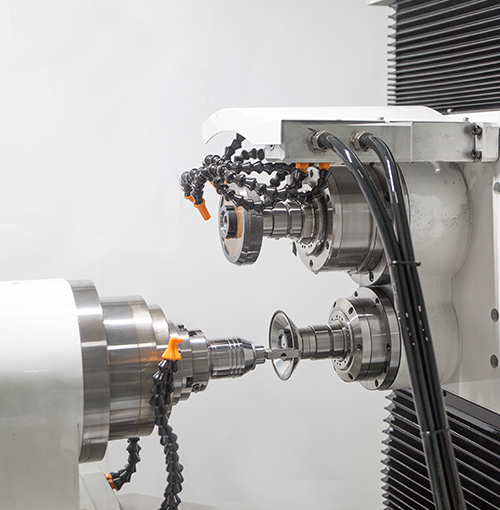

A milling cutter is a cutting tool used in milling machines to remove material from a workpiece. It consists of one or more cutting edges that rotate around an axis to cut material, typically in a circular or helical motion. Milling cutters can be used for a wide range of applications, including creating flat surfaces, slots, pockets, and complex shapes in a variety of materials, including metals, plastics, and composites.

There are several types of milling cutters, including end mills, face mills, ball nose mills, and slot drills. End mills have cutting edges on the end face and periphery and are used for milling flat surfaces, pockets, and slots. Face mills have cutting edges on the periphery and face and are used for milling large flat surfaces. Ball nose mills have a rounded tip and are used for 3D profiling and finishing operations. Slot drills have cutting edges on the periphery and bottom and are used for milling slots and keyways.

What factors should be considered when selecting a milling cutter?What types of materials can be cut with milling cutters?

When selecting a milling cutter, several factors should be considered, including the material being cut, the desired surface finish, the required production rate, and the machine's capabilities. The cutting tool expert can then recommend the appropriate tool geometry, coatings, and cutting parameters to achieve optimal performance.

Milling cutters can be used to cut a wide range of materials, including metals, plastics, composites, and ceramics. The cutting tool material and geometry will depend on the specific properties of the material being cut, such as its hardness, toughness, and thermal conductivity.

What are some common coatings used for milling cutters, and what benefits do they provide?

Common coatings used for milling cutters include titanium nitride (TiN), titanium carbonitride (TiCN), and aluminum titanium nitride (AlTiN). These coatings can provide several benefits, including improved wear resistance, increased lubricity, and reduced friction. TiN is typically used for milling softer materials such as aluminum, while TiCN and AlTiN are used for milling harder materials such as stainless steel.