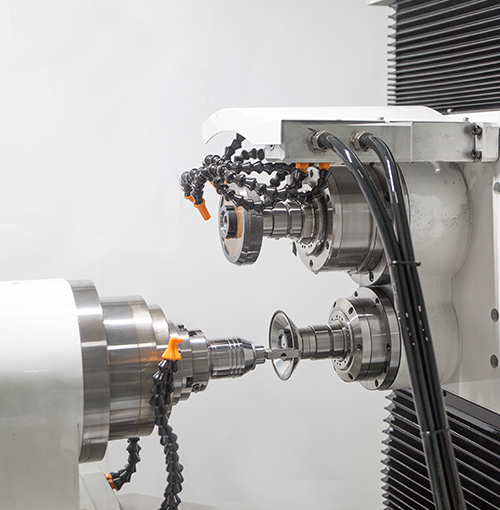

Precision manufacturing of indexable drill bits: from material selection to the cornerstone of high performance

In the modern machining industry, the performance and precision of cutting tools have a vital impact...

Apr 24,2024

1-Positive large rake angle insert, the insert's overall wiper edge design

2- Can be used with many international brands

Hangzhou Chai Cutting tools Co.,Ltd, established in 2012, is a professional Carbide Insert Manufacturers and indexable Carbide Insert factory in China which engaged in the research and development, production, sale and service of various cutting tools. Our main products include CNC turning tools, milling tools, drilling tools, boring tools and many kinds of toolholders, inserts, which apply to a wide range of areas, inlcuding mold manufacturing, vehicles, wind power and nuclear power, railway and aviation industry. Chaitools has gained the ISO9001 quality management system certification and established a complete quality control procedure. After several years' hard working, the performances and indexes of our products is close to or exceeds the cutter of domestic and foreign first-level mainstream brands, and has the well applicability and economy. We also custom Carbide Inserts for turning, milling, drilling other cutting operation.