Industry knowledge

What are some common problems encountered during Chamfering Milling Cutter Holder operations, and how can they be prevented or resolved?

Tool breakage can occur if the tool is subjected to excessive force or if it encounters an unexpected hard spot in the workpiece. To prevent tool breakage, it is important to use the correct cutting parameters, including feed rate, spindle speed, and depth of cut. It is also essential to use a high-quality Chamfering Milling Cutter Holder that is made from a durable material and has a sharp cutting edge. Regular tool inspections can also help to identify any signs of wear or damage before a catastrophic failure occurs.

Poor surface finish can result from inadequate tool geometry, incorrect cutting parameters, or incorrect tool selection. To improve surface finish, it is important to select the appropriate Chamfering Milling Cutter Holder based on the material being machined and the desired finish. The tool geometry should also be chosen carefully to ensure that the tool can remove material smoothly and efficiently. Adjusting the cutting parameters, such as reducing the feed rate or increasing the spindle speed, can also help to improve surface finish.

Chatter marks can occur when the Chamfering Milling Cutter Holder is not rigid enough or when the cutting parameters are incorrect. To eliminate chatter marks, it is essential to use a stable and rigid Chamfering Milling Cutter Holder that can absorb vibrations and maintain stability during cutting. Reducing the depth of cut or increasing the spindle speed can also help to reduce chatter.

Incorrect chamfer angle can result from using the wrong tool or incorrect tool setup. To ensure that the correct chamfer angle is achieved, it is important to select the appropriate Chamfering Milling Cutter Holder that is designed for the desired angle. The tool setup should also be carefully adjusted to ensure that the angle is achieved accurately and consistently.

How are Chamfering Milling Cutter Holders integrated into the broader context of manufacturing processes?

Chamfering Milling Cutter Holders play an important role in the broader context of manufacturing processes. They are a critical component of the machining process and are used to produce precise chamfers on workpieces. Chamfers are often used to remove sharp edges and create a more aesthetically pleasing appearance on parts.

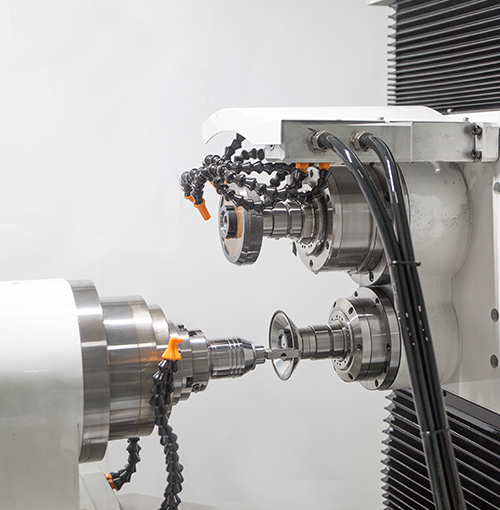

Chamfering Milling Cutter Holders are typically used in conjunction with other cutting tools, such as drills, end mills, and taps, to create complex geometries on workpieces. They are often used in the production of parts for various industries, including automotive, aerospace, and medical devices.

The integration of Chamfering Milling Cutter Holders into manufacturing processes requires careful consideration of several factors, including the material being machined, the desired geometry, and the required accuracy. Machinists must select the appropriate cutting parameters, including spindle speed, feed rate, and depth of cut, to ensure that the tool performs optimally and achieves the desired chamfer geometry.

Chamfering Milling Cutter Holders can also be integrated into computer-controlled machining processes, such as CNC machining. CNC machines use pre-programmed software to control the movement of the cutting tools, ensuring high accuracy and repeatability. The use of Chamfering Milling Cutter Holders in CNC machining processes can increase productivity and efficiency, allowing for faster production of high-quality parts.

Additionally, the use of Chamfering Milling Cutter Holders can help reduce production costs by minimizing the need for additional finishing operations, such as deburring. By creating precise chamfers during the machining process, the need for additional post-processing operations can be reduced or eliminated, saving time and resources.

What is a Chamfering Milling Cutter Holder, and what are its functions?How do Chamfering Milling Cutter Holders differ from other types of milling cutters?

A Chamfering Milling Cutter Holder is a tool used in milling operations to create chamfers or beveled edges on the edges of a workpiece. Chamfering is a crucial step in many manufacturing processes, as it helps to reduce the risk of sharp edges causing injury, improves the appearance of the finished product, and facilitates easier assembly of components. Chamfering Milling Cutter Holders are used in conjunction with milling machines, which use rotary cutting tools to remove material from a workpiece.

Chamfering Milling Cutter Holders are designed specifically for creating chamfers, whereas other types of milling cutters are used for a variety of different cutting operations, such as drilling, boring, and slotting. Chamfering Milling Cutter Holders have a specialized cutting edge that is angled to create a beveled edge on the workpiece, whereas other milling cutters have straight or curved cutting edges for other types of operations.