Industry knowledge

What is an indexable end milling cutter, and what are its applications?How can indexable end milling cutters be optimized for specific applications?

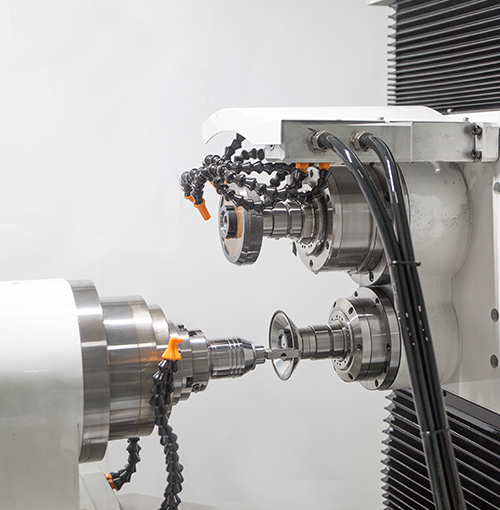

An indexable end milling cutter is a cutting tool used in milling machines to remove material from a workpiece. It consists of one or more cutting edges that rotate around an axis to cut material, typically in a circular or helical motion. Indexable end milling cutters are used for a wide range of applications, including creating flat surfaces, slots, pockets, and complex shapes in a variety of materials, including metals, plastics, and composites.

Indexable end milling cutters can be optimized for specific applications by adjusting the insert geometry, adding coatings, and adjusting the cutting parameters. For example, a high-feed mill may be used for high-speed machining of tough materials, while a ball nose mill may be used for 3D profiling and finishing operations. Coatings may be added to improve wear resistance or reduce friction, and cutting parameters may be adjusted to optimize performance for the specific material being cut.

What are the different types of indexable end milling cutters?What are the advantages of using indexable end milling cutters?

There are several types of indexable end milling cutters, including face mills, ball nose mills, and high-feed mills. Face mills have cutting edges on the periphery and face and are used for milling large flat surfaces. Ball nose mills have a rounded tip and are used for 3D profiling and finishing operations. High-feed mills have a small diameter and a high number of teeth and are used for high-speed machining of tough materials.

The use of indexable end milling cutters offers several advantages, including reduced tooling costs, improved tool life, and increased efficiency. Indexable cutters allow for the replacement of only the worn or damaged insert, reducing the cost of tooling. The use of high-quality inserts can improve tool life and reduce downtime for tool changes. Indexable cutters can also be easily repositioned to optimize cutting performance, reducing machining time and increasing efficiency.

How are indexable end milling cutters assembled and adjusted?What types of materials can be cut with indexable end milling cutters?

Indexable end milling cutters are typically assembled by inserting one or more indexable inserts into the cutter body and securing them with screws or clamps. The inserts can be adjusted to achieve the desired cutting geometry by adjusting their position within the cutter body. The cutting parameters can also be adjusted by changing the insert's rake angle, clearance angle, and chipbreaker geometry.

Indexable end milling cutters can be used to cut a wide range of materials, including metals, plastics, composites, and ceramics. The cutting tool material and geometry will depend on the specific properties of the material being cut, such as its hardness, toughness, and thermal conductivity.