Industry knowledge

What materials are grooving cutters typically used for?What are the different types of grooving cutters available, and how do they differ?

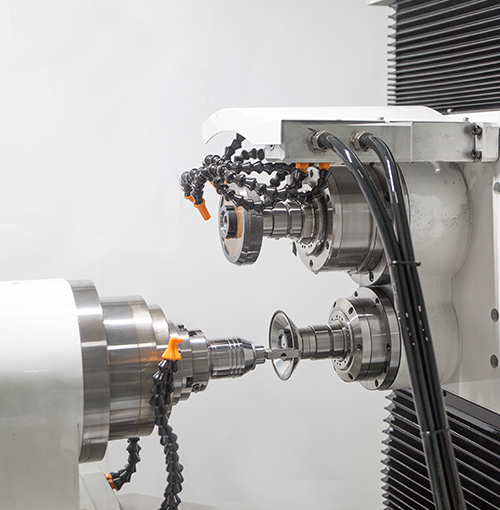

Grooving cutters are typically used for cutting grooves and slots in a variety of materials, including metals, plastics, and woods. The specific material that a grooving cutter is best suited for will depend on the material's properties, such as its hardness and density, as well as the cutter's design and material.

There are several types of grooving cutters available, including straight flute, spiral flute, and indexable insert cutters. Straight flute cutters are the most basic type of grooving cutter and feature a simple straight design. Spiral flute cutters have a helical design that helps to reduce chatter and improve chip evacuation. Indexable insert cutters use replaceable cutting inserts that can be rotated or replaced when worn.

How do you select the right grooving cutter for a specific application?What are some common mistakes to avoid when using grooving cutters?

When selecting a grooving cutter for a specific application, there are several factors to consider, including the material being cut, the size and depth of the groove or slot, the surface finish required, and the machine being used. It is important to choose a cutter that is designed for the specific material being cut and that is capable of producing the desired surface finish.

One common mistake when using grooving cutters is using the wrong cutting speed or feed rate, which can lead to poor surface finish, tool wear, and even damage to the workpiece or cutting tool. It is also important to properly secure the workpiece and cutting tool to prevent movement or chatter during cutting.

How do you maintain and care for grooving cutters to ensure optimal performance and longevity?

Clean the cutter after each use: After using the grooving cutter, clean it thoroughly with a soft brush or cloth to remove any chips, dirt, or debris that may have accumulated. This will help prevent corrosion and ensure the cutter remains sharp.

Store the cutter properly: Store the cutter in a dry and cool place, away from humidity and extreme temperatures. Use protective sleeves or boxes to prevent damage to the cutting edges.

Inspect the cutter regularly: Check the cutter periodically for signs of wear or damage. Look for cracks, chips, or other damage to the cutting edges, and ensure that the cutter is still within its specified tolerance range. If the cutter is damaged, it should be replaced or repaired promptly.

Sharpen or replace the cutting edges as needed: When the cutting edges become dull or damaged, they should be sharpened or replaced promptly. Dull or damaged cutting edges can lead to poor performance, tool wear, and even damage to the workpiece.

Use proper lubrication and cooling: Lubrication and cooling are important for preventing overheating and tool wear. Use the recommended lubricant and coolant for the material being cut and ensure that the cutting edges are properly lubricated and cooled during cutting.