Industry knowledge

What are the different types of grooving tool holders available, and how do they differ?What are the benefits of using grooving tool holders in machining applications?

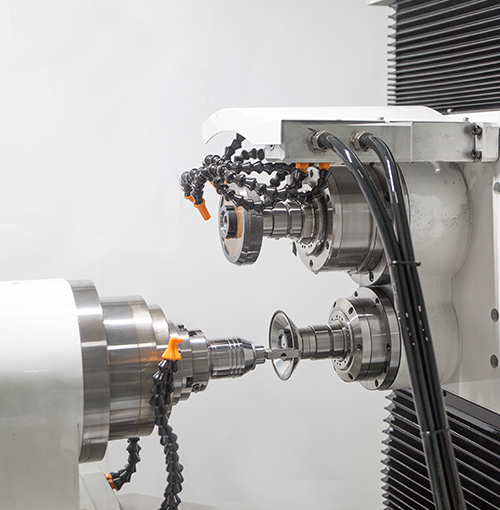

There are several types of grooving tool holders available, including boring bar holders, dovetail holders, and block holders. Boring bar holders are designed for use with boring bars, while dovetail holders are designed for use with inserts that have a dovetail shape. Block holders are used for holding square or rectangular inserts. Each type of holder is designed to accommodate different types of inserts and cutting tools.

Using grooving tool holders can provide several benefits in machining applications, including improved accuracy and surface finish, reduced tool wear and breakage, and increased productivity and efficiency. By using the right holder for the cutting tool being used, the cutting forces can be properly directed and controlled, resulting in better performance and longer tool life. Additionally, using a holder can help reduce setup time and improve consistency between parts.

How do you select the right grooving tool holder for a specific application?What are some common mistakes to avoid when using grooving tool holders?

When selecting a grooving tool holder for a specific application, there are several factors to consider, including the material being cut, the size and depth of the groove or slot, and the machine being used. It is important to choose a holder that is compatible with the cutting tool being used and that is capable of producing the desired surface finish.

One common mistake when using grooving tool holders is using the wrong type of holder for the cutting tool being used. This can lead to poor performance, tool wear, and even damage to the workpiece or holder. It is also important to ensure that the holder is properly tightened and secured to prevent movement or chatter during cutting.

How do you maintain and care for grooving tool holders to ensure optimal performance and longevity?

To maintain and care for grooving tool holders and ensure optimal performance and longevity, the following steps should be taken:

Clean the holder after each use to remove any chips or debris that may have accumulated.

Inspect the holder periodically for signs of wear or damage and replace or repair as needed.

Store the holder properly to prevent damage or corrosion.

Lubricate the holder as appropriate to ensure smooth operation and prevent wear.