Industry knowledge

What is a solid carbide end mill cutter, and what are its applications?What are the latest advancements in solid carbide end mill cutter technology?

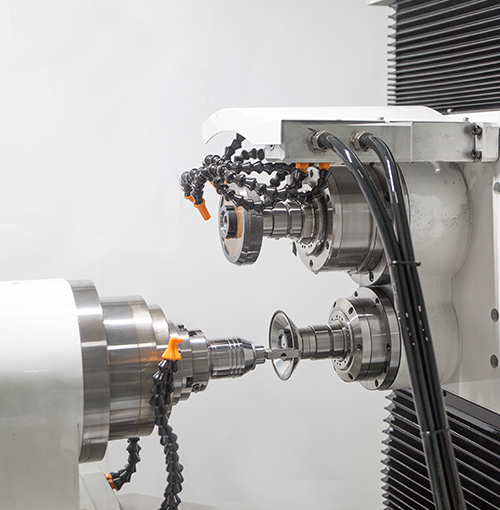

A solid carbide end mill cutter is a cutting tool used in milling machines to remove material from a workpiece. It consists of a cutting edge on the end of a cylindrical body, which rotates around an axis to cut material in a circular motion. Solid carbide end mills are widely used in various industries, including aerospace, automotive, and medical, to create complex shapes and contours, drill holes, and produce high-precision surface finishes.

Recent advancements in solid carbide end mill cutter technology include the use of advanced coatings and materials, as well as the integration of cutting-edge technologies such as IoT and AI. The use of advanced coatings such as diamond and other hard materials can help improve wear resistance and extend tool life. The use of smart cutting tools, which incorporate sensors and other technologies, can help optimize cutting parameters and improve process efficiency.

What are the advantages of using a solid carbide end mill cutter?What factors should be considered when selecting a solid carbide end mill cutter?

The use of a solid carbide end mill cutter offers several advantages, including increased tool life, improved machining accuracy, and reduced production costs. Solid carbide end mills are highly durable and wear-resistant, which results in longer tool life and fewer tool changes. They also produce a high-quality surface finish, reducing the need for secondary operations such as polishing or grinding. The use of advanced coatings, such as TiAlN and TiCN, can further enhance the tool's performance and durability.

Several factors should be considered when selecting a solid carbide end mill cutter, including the material being machined, the desired surface finish, the machine's spindle speed and horsepower, and the size of the workpiece. The cutting tool material and geometry should also be considered, as they will affect the tool's performance and durability. The type of end mill, such as a square end or ball nose, should also be considered based on the specific machining application.

What are the different types of solid carbide end mill cutters?What are the different types of cutting tool geometries used in solid carbide end mill cutters?

There are several types of solid carbide end mill cutters, including square end mills, ball nose end mills, corner radius end mills, and roughing end mills. Square end mills are used for general milling applications, while ball nose end mills are used for machining curved surfaces and contours. Corner radius end mills are used for creating rounded corners, and roughing end mills are used for removing large amounts of material quickly.

There are several types of cutting tool geometries used in solid carbide end mill cutters, including two-flute, three-flute, and four-flute designs. Two-flute end mills are typically used for softer materials and produce a smoother surface finish. Three-flute end mills are suitable for a wider range of materials and produce a more aggressive cutting action. Four-flute end mills are suitable for harder materials and produce a higher chip load.