Industry knowledge

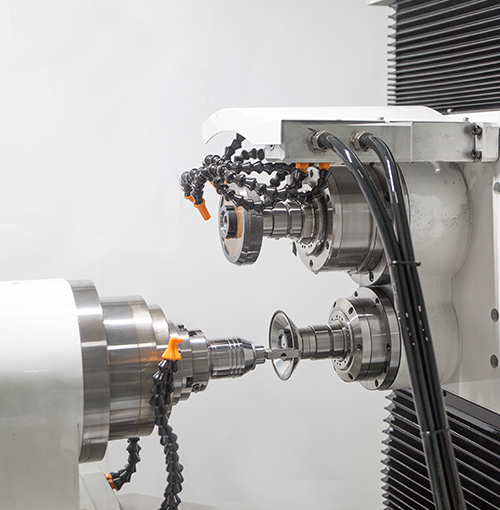

Groove Slot Milling Cutters are used in milling machines to create grooves or slots in workpieces. The cutter is attached to the machine's spindle, which rotates the cutter. The cutter makes contact with the workpiece, and the machine moves the cutter across the workpiece to create the desired groove or slot.

The shape and size of the groove or slot are determined by the shape and size of the cutter. The cutter's teeth remove material from the workpiece, creating the groove or slot.

What factors should be considered while selecting a Groove Slot Milling Cutter?What types of slot milling cutters are available in the market?

Groove Slot Milling Cutters are used to create grooves or slots in workpieces. The type of cutter needed depends on the size and shape of the groove or slot required. The following are some of the different types of Groove Slot Milling Cutters available in the market:

Straight Tooth Cutter: This type of cutter has straight teeth and is used for general-purpose milling.

Staggered Tooth Cutter: This type of cutter has staggered teeth and is used for heavy-duty milling.

Side Milling Cutter: This type of cutter has teeth on the side and is used for milling slots or grooves on the side of a workpiece.

T-Slot Cutter: This type of cutter has a T-shaped slot and is used for milling T-slots in workpieces.

Woodruff Key Cutter: This type of cutter is used to create keyways for Woodruff keys.

While selecting a Groove Slot Milling Cutter, the following factors should be considered:

Type of material being machined: Different materials require different types of cutters.

Width and depth of the groove or slot: The cutter should be compatible with the desired width and depth of the groove or slot.

Type of operation: The cutter should be suitable for the type of operation, such as roughing or finishing.

Rigidity: The cutter should be rigid enough to prevent vibration and chatter during operation.

Accuracy: The cutter should be accurate enough to maintain the desired level of precision.

What are the common problems faced while using Groove Slot Milling Cutters and how to overcome them?

Some common problems faced while using Groove Slot Milling Cutters are:

Chatter: Chatter is caused by vibration in the machine or the cutter. To overcome chatter, the machine should be properly tuned and the cutter should be rigid enough to prevent vibration.

Chip clogging: Chip clogging occurs when chips get stuck in the cutter's teeth, reducing the cutting efficiency. To overcome chip clogging, the machine's coolant system should be used to flush away the chips.

Wear and tear: Over time, the cutter's teeth may become worn or damaged, reducing its effectiveness. To overcome wear and tear, the cutter should be regularly checked and replaced if necessary.