Industry knowledge

Corn Milling Cutter Holders are used in milling machines to hold and rotate corn milling cutters. The type of holder needed depends on the size and shape of the cutter, as well as the machine's spindle taper. The following are some of the different types of Corn Milling Cutter Holders available in the market:

End Mill Holder: This type of holder is designed to hold end mills and is available in various sizes and shapes. It has a set screw that secures the end mill in place.

Shell Mill Holder: This type of holder is used for holding shell mills. It has a cylindrical body and a flat end surface that accommodates the shell mill's mounting.

Collet Chuck: Collet chucks are used for holding milling cutters with straight shanks. The collet chuck holds the cutter in place by compressing the collet around the shank.

Morse Taper Holder: This type of holder is used for holding milling cutters with Morse tapers. The Morse taper holder is designed to fit into the machine's spindle taper.

Hydraulic Chuck: Hydraulic chucks are used for holding milling cutters with large diameters. They have a hydraulic system that tightens the chuck around the cutter.

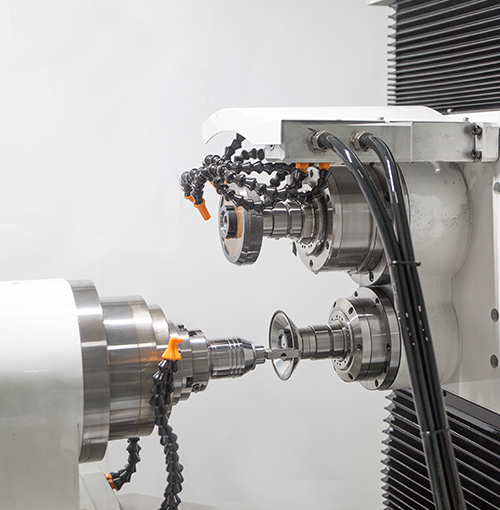

Corn Milling Cutter Holders are used to hold and rotate milling cutters in milling machines. The holder is attached to the machine's spindle, which rotates the holder and the cutter. The cutter is held in place by the holder, which secures it with set screws, collets, or chucks.

When the machine is turned on, the spindle rotates, and the milling cutter rotates along with it. The cutter makes contact with the workpiece, and the machine moves the cutter across the workpiece to create the desired shape or pattern.

What factors should be considered while selecting a Corn Milling Cutter Holder?

While selecting a Corn Milling Cutter Holder, the following factors should be considered:

Size and shape of the cutter: The holder should be compatible with the size and shape of the cutter.

Machine spindle taper: The holder should be compatible with the machine's spindle taper.

Type of material being machined: Different materials require different types of cutters and holders.

Type of operation: The holder should be suitable for the type of operation, such as roughing or finishing.

Rigidity: The holder should be rigid enough to prevent vibration and chatter during operation.

Accuracy: The holder should be accurate enough to maintain the desired level of precision.